Chapter 26 Object-Oriented Method and the Relationship Between Structure and Function of Technical Artifacts

Abstract

The abstract discusses a challenge in the philosophy of technology and engineering science regarding the relationship between the structure and function of a technical artifact. The key points are:

Challenge in Philosophy of Technology and Engineering Science:

- There's a need to understand the relationship between a technical artifact's structure (how it's built) and its function (what it does). However, current philosophical approaches in technology and engineering science struggle to support the idea that a significant relationship exists between these two aspects.

Empirical Turn and Functional Decomposition:

- The Empirical Turn, a recent development in the philosophy of technology and engineering science, attempts to address this issue.

- Jeroen de Ridder's 'Functional Decomposition' is a reductive design methodology presented in this context. It attempts to explain the structure-function relationship through rational reconstruction, which is a method of understanding how a technical artifact works by breaking it down into simpler, understandable units.

Limitation in Context of Creative Design:

- De Ridder’s methodology, while useful in some contexts, falls short in explaining the structure-function relationship in the context of creative design, where innovation and novel ideas are critical.

Proposal of a New Model – Object-Oriented Method:

- The author proposes a new model, the Object-Oriented Method, which adopts a holistic approach. Unlike the Functional Decomposition, which breaks down artifacts into smaller parts, the Object-Oriented Method looks at the artifact as a whole.

- This holistic methodology aims to better explain the positive relationship between structure and function, especially in contexts involving creative design processes.

Addressing Underdetermination and Realizability Constraints:

- The new model also addresses two phenomena associated with the structure-function relationship:

- Underdetermination: The idea that a single function could be realized through multiple different structures.

- Realizability Constraints: The limitations or requirements that the physical and practical aspects of a structure impose on the realization of a function.

In summary, the abstract introduces a new holistic model, the Object-Oriented Method, to explain the relationship between the structure and function of technical artifacts, particularly addressing gaps in the context of creative design and explaining phenomena like underdetermination and realizability constraints.

26.1 Introduction

The introduction to this chapter delves into a fundamental problem in the philosophy of technology and engineering science: understanding the relationship between the structure and function of technical artifacts. Key points include:

Dual Nature of Technical Artifacts (DNTA):

- Peter Kroes and others propose that a complete description of a technical artifact involves both a physical/structural description and a functional description. This concept is known as the Dual Nature of Technical Artifacts (DNTA), which raises various philosophical questions and challenges.

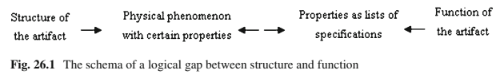

Discontinuity Between Structure and Function:

- Analytical philosophical approaches often find no direct, positive relationship between structure and function. Kroes argued that a logical gap exists between the two, suggesting that a functional description cannot be deduced from a structural description and vice versa.

Challenges in Understanding Structure-Function Relationship:

- The relationship between structure and function in technical artifacts is complex, raising issues like underdetermination (multiple structures can realize the same function) and realizability constraints (inferences between function and structure).

Empirical Turn (ET) in Philosophy of Technology:

- ET advocates for philosophical analysis of technology based on empirically sound descriptions. It suggests that understanding design methodology can offer insights into the relationship between structure and function in technical artifacts.

Functional Decomposition (FD) and Its Limitations:

- Jeroen de Ridder’s Functional Decomposition (FD), a reductive design methodology, attempts to describe the structure-function relationship. However, FD falls short in the context of creative design, where innovative and novel approaches are crucial.

Proposal of Object-Oriented Method (OOM):

- In response to the limitations of FD, the Object-Oriented Method (OOM) is proposed as a holistic design methodology. This method is positioned as a potential way to understand the positive relationship between structure and function, particularly in creative design contexts.

OOM’s Ability to Address Underdetermination and Realizability Constraints:

- The chapter aims to show how OOM can explain the phenomena of underdetermination and realizability constraints within the context of creative design.

- Scope and Methodology:

- The chapter focuses on technical artifacts as physical structures constructed by humans for specific purposes. It assumes that the function of the artifact is known before the design process begins.

The following sections of the chapter are outlined as introducing critical concepts, presenting the model and strategy of OOM, analyzing a mold design case study, and demonstrating how OOM explains the relationship between structure and function, as well as addressing underdetermination and realizability constraints. The conclusion summarizes the findings.

26.2 Object-Oriented Method: Concepts

This section introduces the Object-Oriented Method (OOM) and its foundational concepts: Object and Class.

Object:

- An Object is an entity characterized by its status (structure) and behaviors (function). This aligns with the Dual Nature of Technical Artifacts (DNTA), where a technical artifact embodies both structural and functional attributes.

Class:

- A Class represents the common characteristics of objects. It’s a concept abstracted from objects, essentially defining a type or kind of object. A single object can belong to different classes based on its features. For example, a glass cup is part of the 'cup' class (functional classification) and the 'glass artifact' class (structural classification).

Contexts of Human Behaviors:

- Technical artifacts relate to two main contexts of human behaviors: use and design. In the context of use, the function (behavior) of an artifact is emphasized, while its structure is less apparent (like a black box). Conversely, in the context of design, the focus is on the physical system (structure), and the function is less emphasized.

Underdetermination:

- There is an underdetermination relationship between structure and function. For instance, the function of 'drinking' can be fulfilled by various types of cups (glass, paper, etc.). This illustrates that multiple structures can realize the same function.

Technical Function and Structure of the Class:

- In the context of use, the focus is on the Technical Function of the class rather than the function of an individual object. In the context of design, the emphasis is on the Structure of the class, not just the structure of a single object.

The OOM thus presents a holistic approach to understanding the relationship between structure and function in technical artifacts, emphasizing the significance of classifying objects in different contexts (use and design) and recognizing the underdetermination between structure and function.

26.3 Strategy and Model

This section describes a new strategy and model for understanding the relationship between structure and function in technical artifacts, contrasting with Jeroen de Ridder’s Functional Decomposition method which uses a top-down approach. The proposed strategy, based on the Object-Oriented Method (OOM), adopts a bottom-up approach:

Bottom-Up Approach:

- Unlike Ridder's top-down strategy, this approach starts from the specific details of an artifact and works its way up to a broader understanding.

Exploring Relationships Indirectly:

- Similar to Ridder, the model seeks to understand the structure-function relationship indirectly. It utilizes the Function-Behavior-Structure (FBS) model, focusing on behaviors as an intermediary between structure and function.

Mathematical Function Representation:

- Behaviors are described as mathematical functions (MF). MF-S(t) represents the behaviors reflecting the structure of a technical artifact, and MF-TF(t) represents the behaviors reflecting the function of a technical artifact.

Equality of Mathematical Functions:

- The relationship between function and structure emerges when MF-S(t) and MF-TF(t) are equal.

Mathematical Function of Class (MFOC) Method:

- This method includes several levels:

- The bottom level focuses on the artifact as an object, with structural and functional descriptions.

- The second level addresses two contexts: the context of use (dominated by the class structure of technical artifacts) and the context of design (dominated by the class technical function).

- The third level involves mathematical modeling of MF-TF(t) and MF-S(t) to represent spatiotemporal sub-functions.

- The top level formulates the entire MFOC model, where the relationship between structure and function is realized if the subtraction between MF-S(t) and MF-TF(t) is within an acceptable error margin (ε).

Iterative Process:

- If the comparison between MF-S(t) and MF-TF(t) exceeds the error ε, the process loops back to revise the function, sub-behaviors, or decomposition rules.

This approach, focusing on the intricate relationship between the structure and function of technical artifacts, provides a holistic view by integrating mathematical modeling and considering the dual contexts in which artifacts operate. The iterative nature of the model allows for continuous refinement and alignment of structure and function.

Real-World Example:

Imagine you're designing a chair. The function of the chair (to provide a comfortable seating experience) can be quantified in terms of ergonomic parameters, weight distribution, support, etc. This is your MF-TF(t).

Now, you create a structural design for the chair, considering factors like material strength, dimensions, shape, etc. This design is translated into a mathematical model - your MF-S(t).

By comparing MF-S(t) with MF-TF(t), you are essentially checking if the structure you've designed will fulfill the intended function (ergonomic comfort) effectively. The subtraction here is a figurative way to measure the alignment or discrepancy between your design's structure and its intended function.

The error margin (ε) in this context could represent tolerable deviations in comfort or support levels due to design constraints. If the discrepancy between MF-S(t) and MF-TF(t) is within this margin, it means your chair's design (structure) effectively fulfills its intended function within acceptable limits.

In summary, this approach in OOM uses mathematical models to rigorously quantify and align the structure and function of a design, ensuring that technical artifacts not only meet their intended use but also adhere to practical design constraints.

26.4 Mold Design: A Case

The case study presented in this section involves a Japanese factory tasked with designing and manufacturing a mold that could produce a circular copper annulus from a copper plate. This task was challenging because achieving a precise circular shape in mold design is notoriously difficult, and the client's requirements included a very tight margin of error (0.05 mm in diameter).

Key Steps in the Process:

Initial Requirements and Strategy: The engineers first clearly defined the client's requirements. They realized that traditional mold design methods were the only available approach due to time constraints.

Design and Testing: The engineers began with a traditional method of mold design, dividing the process into four sub-periods, each involving specific actions like slitting the copper plate, bending it, and finally shaping it into a circle. However, initial tests did not meet the required precision.

In-depth Analysis and Database Review: After failing to find the problem through standard testing and adjustments, the engineers paused testing to review their factory's database of past projects. This review included previous attempts at circular mold designs, even those that had failed.

Identification of the Issue: Through this review and subsequent testing, they discovered that the issue was not with the components or procedures per se, but with the elastic nature of the metal plate. It became nearly circular under the mold's pressure but slightly sprang back when the pressure was removed, causing the error.

Creative Revision and Problem-Solving: Lacking a specific theory or tool to guide the revision, the engineers relied on their professional experience and instinct. The chief engineer, in particular, used trial-and-error methods to adjust the arc surface of the mold component.

Successful Outcome: Just in time for the client's visit, the engineers managed to produce a mold that met the requirements, with an average error of about 0.03 mm.

Conclusion:

This case study highlights the challenges of creative design in engineering, particularly when dealing with non-prototypical, complex tasks like mold design for precise shapes. The engineers' ability to combine traditional methods with an innovative, experience-based approach was key to their success. The case also illustrates the importance of thorough analysis, including learning from past failures, and the crucial role of skilled, intuitive problem-solving in engineering design.

26.5 Modeling

The section "26.5 Modeling" from the chapter discusses how the relationship between the structure and function of a technical artifact can be modeled and understood through a practical case study of mold design. Here's a concise explanation:

Client's Requirements: The client needed a mold to produce a circular copper annulus with an error margin in diameter not exceeding 0.05 mm. The client was primarily concerned with the functional outcome (the copper annulus meeting the error requirements) rather than the specific structural details of the mold.

Translation of Requirements: Before designing the mold, engineers had to translate the client's vague functional requirements into explicit design goals. They used functional decomposition to envision the mold's operation in several sub-periods, each corresponding to a step in the process of bending the copper plate into a circular shape.

Mathematical Function Modeling: The engineers modeled each sub-period of the mold's operation as a spatiotemporal behavior, represented mathematically. For example, different stages of bending the copper plate were mapped as points in spatiotemporal coordinates. The overall operation was expressed as a mathematical function of technical function (MF-TF(t)).

Testing and Revision: Initial tests of the mold did not meet the error margin requirements. The engineers realized that the elastic properties of the metal caused deviations when the pressure was released. They used their professional experience and past project records to identify and correct the issue.

Final Outcome and Error Margin: The final mold produced copper annuli with an average error of 0.03 mm, within the acceptable margin. In this case, the slight elasticity of the metal (a structural aspect) was considered negligible in the context of the mold's functional performance.

General Model of Structure-Function Relationship: The chapter proposes a general model where the relationship between structure (physical behavior) and function (technical function) of a technical artifact is established through mathematical functions. If the difference between the mathematical functions representing structure and function is within an acceptable error margin (ε), a positive relationship between structure and function is considered to exist.

In summary, the chapter demonstrates how engineers can bridge the gap between structural and functional aspects of a technical artifact through a process of mathematical modeling, empirical testing, and iterative design, ultimately achieving a functional product that meets specific requirements.

Comments

Post a Comment